Modine Wind Tunnels Help Define/Develop Products and Safety Through Science

Racine Technical Center wind tunnels cover all the bases of Modine products, from military vehicles to cell-tower antennas

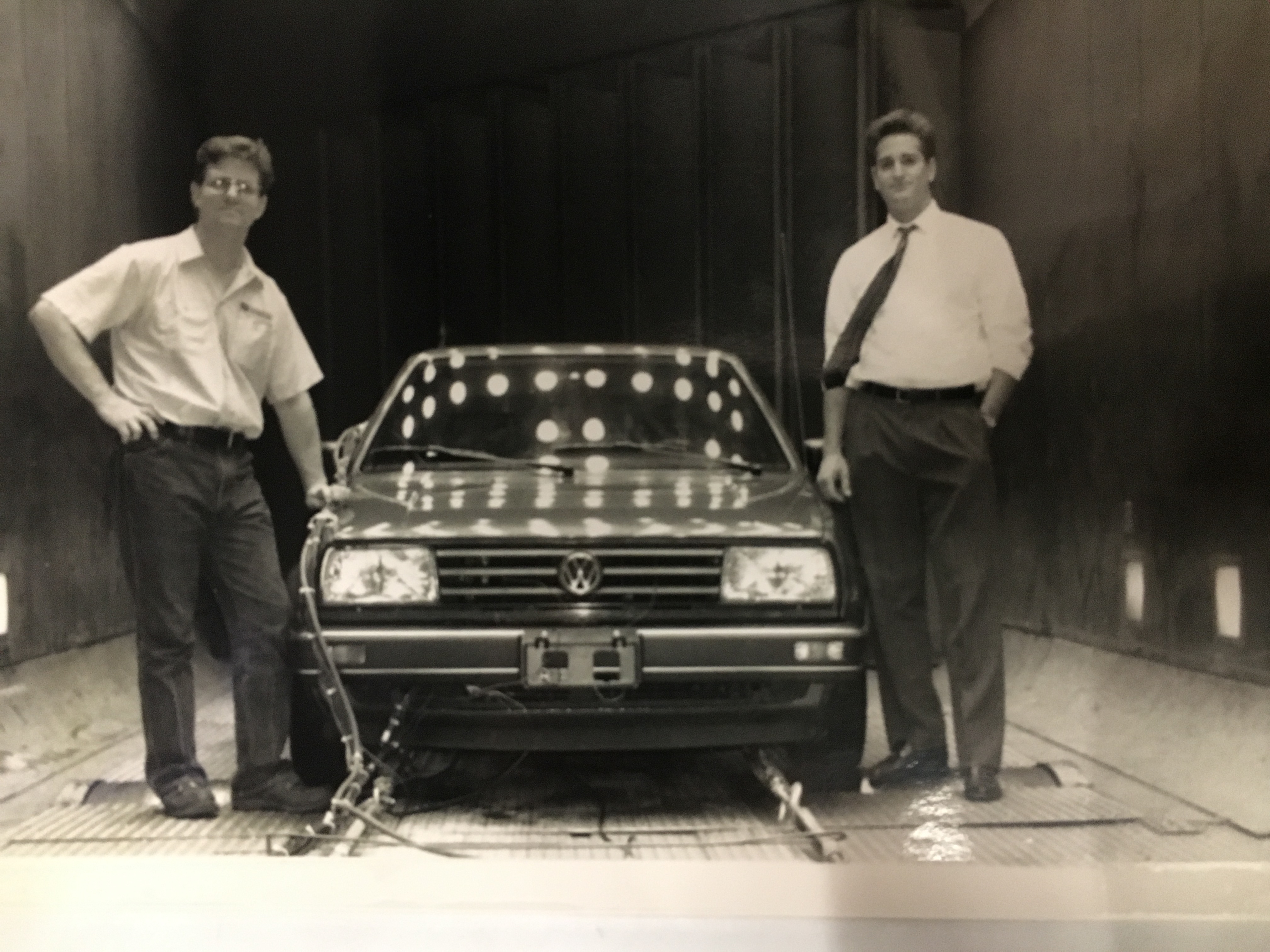

Modine’s two wind tunnels have tested iconic American brands, cellular antennas, a new generation of combat vehicle and the mettle of a Milwaukee meteorologist. We have tested numerous Modine HVAC products over the years, as well as our vehicle heat-transfer products, in both wind tunnels at our Racine, Wisconsin headquarters. The first one was built in 1941 and generates air flow using a propeller from a B-10 bomber. The newest wind tunnel was built in 2000 to accommodate the much larger vehicles going down the road today compared to 1941. It also has increased capabilities in temperature control and a maximum wind speed of 150 mph. The tunnel can simulate ambient temperatures, high winds (obviously) and humidity. It is a rigorous test environment that has been used by some of the world’s biggest business names (which are not used here for reasons of business propriety).

Here are seven of the wind tunnels’ interesting test runs, which are generally paid for by the company doing the testing.

- A cell-tower antenna was subject to speeds of up to 150 mph. At one point it hit a natural frequency and went “haywire.” The antenna’s product engineers were able to modify that frequency point and repeated the test. The test results

created an antenna that can withstand most hurricane-force winds. - One of America’s most iconic motorcycle manufacturers contain Modine product, and the manufacturer can use the wind tunnel to develop/improve certain characteristics of the motorcycle itself, as well as the Modine heat exchangers used on the bikes.

- Other motorcycle manufactures have used the test facility to prove out rider comfort against heat emanating from the bike’s engine.

- Various electric car manufacturers have used the Modine wind tunnel to test the powertrain, battery and passenger cooling systems of their new age vehicles, many of which include several Modine heat exchangers(front end radiator/condenser/e-fan modules, chillers and oil coolers). The auto company wanted to see how well our heat exchanger can meet their specifications. Other tests confirmed/improved passenger comfort and other vehicle systems.

- Vehicle air conditioning systems can be put to the test. Test vehicles can be subjected to high ambient temperatures, simulated sun/solar loads and high humidity to replicate a hot and muggy sunny day. These simulatedharsh settings help guide any neededimprovements to the vehicle’s air conditioning system.

- Municipalities and manufacturers have used Modine testing facilities to set standards for defrosting windshields and cold start testing on city buses and other publicly owned vehicles, such as fire en

gines and school buses.

gines and school buses. - One wind-tunnel client builds mine-resistant fighting vehicles for the military. Their troop carriers have been tested in our tunnel to gauge the level of comfort available for troops transported in the vehicle, especially during use in a hot, sun-soaked desert setting.

Our wind tunnels are used for research and development purposes ranging from stationary generator sets (large ones used at hospitals and other power critical locations); signs/antennas; motorcycles; passenger automobiles; farm tractors; front-end loaders; military vehicles; school/city buses; and the trucks moving freight down our highways! There are a very limited number of such testing sites in the U.S., and that’s why companies of all stripes seek us out for testing.

Oh, about the meteorologist. The Milwaukee weatherman withstood sustained winds of about 100 mph, which is roughly the low end of an E1 tornado.