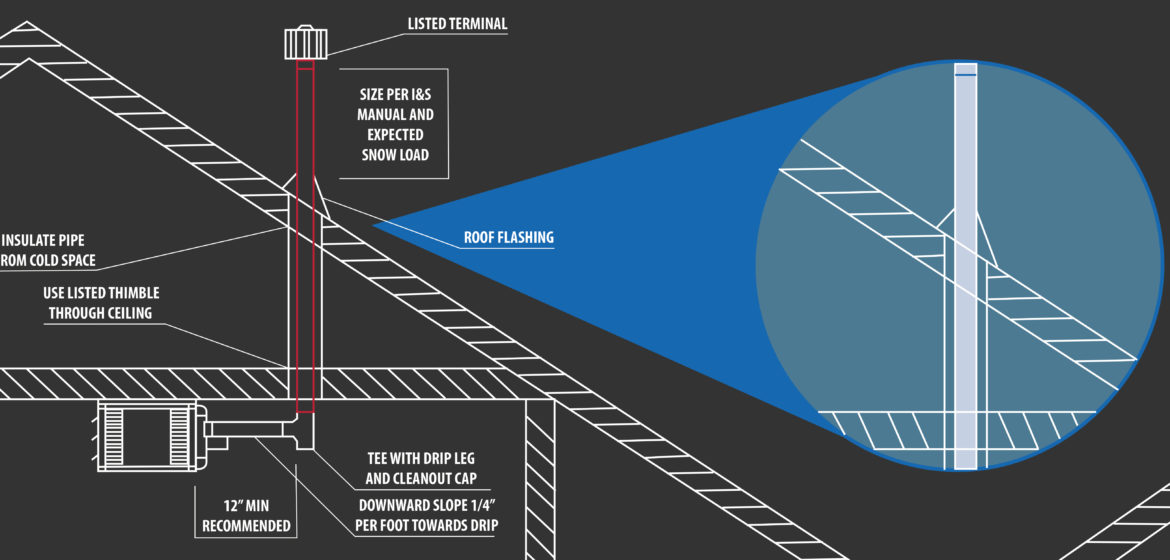

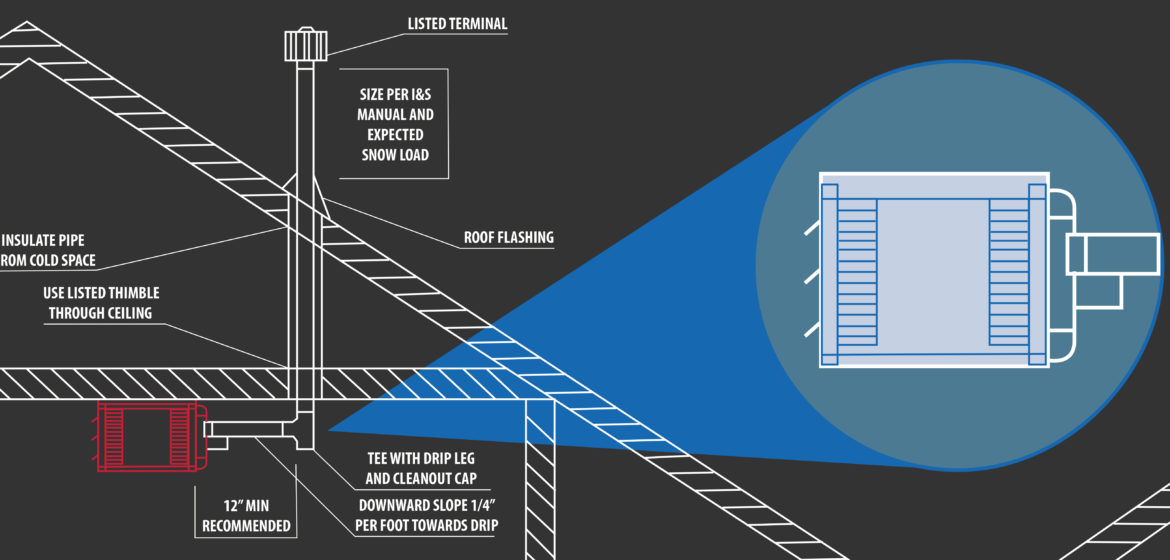

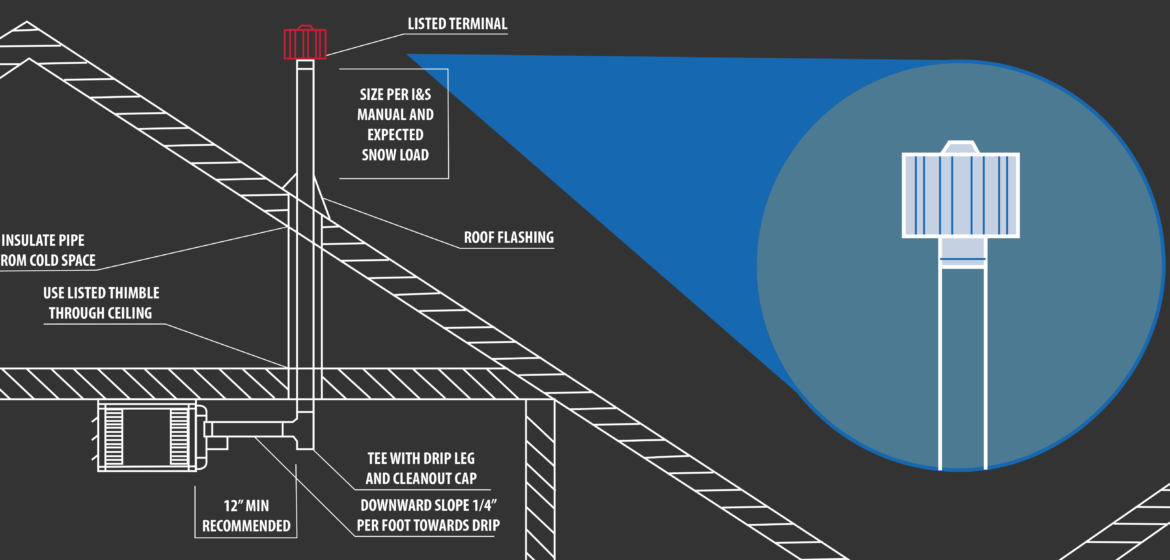

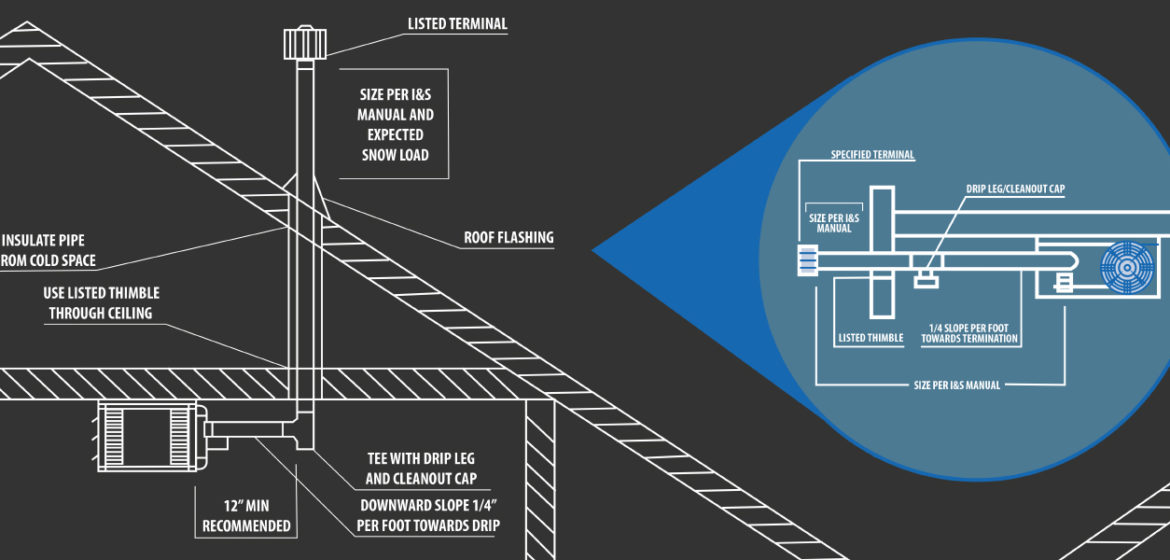

Seven steps to make sure your heater is well-vented

It’s imperative that heating equipment and its components be properly piped, wired, suspended, and vented during installation. Any effort to cut corners can lead to big problems and potential health and safety issues.

A common issue is improper or inadequate vent systems. Remember: A heating system is only as good as its venting system. Poor venting affects the proper combustion of fuel, and can lead to flue exhaust leaks within the space.

Changing standards governing unit heaters in North America can compound the issue. CSA International Requirement 10.96 and CR 96-005 were combined with ANSI Z83.8 / CSA 2.6 to create one standard for all unit heaters sold in the United States and Canada. Among the changes, for instance, was the elimination of an exemption that allowed Category I horizontal venting in some residential applications.

Properly venting your Modine heater can ensure a long life of warmth and comfort for whatever application you choose

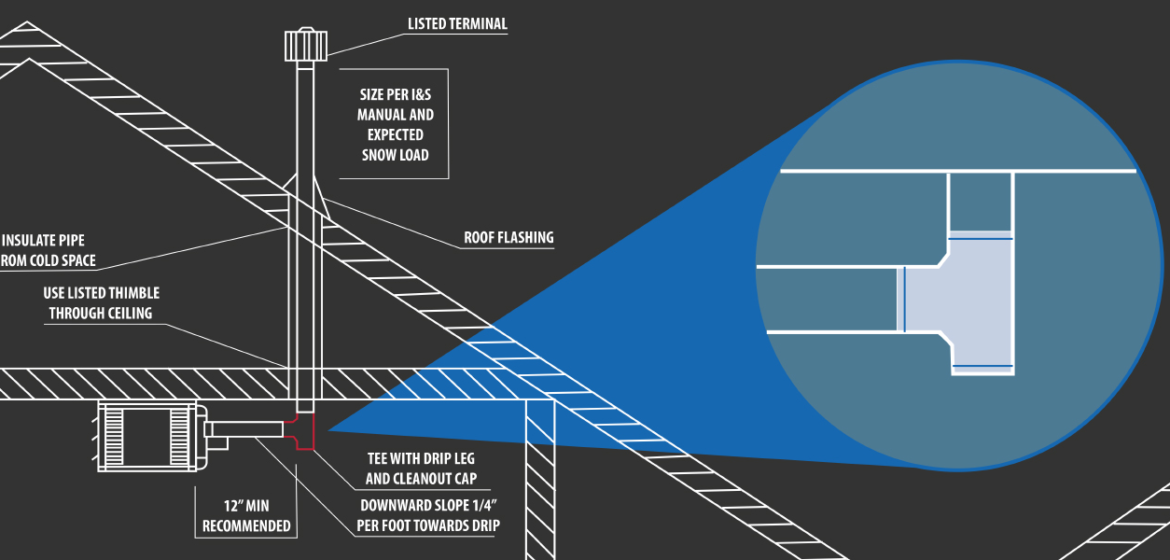

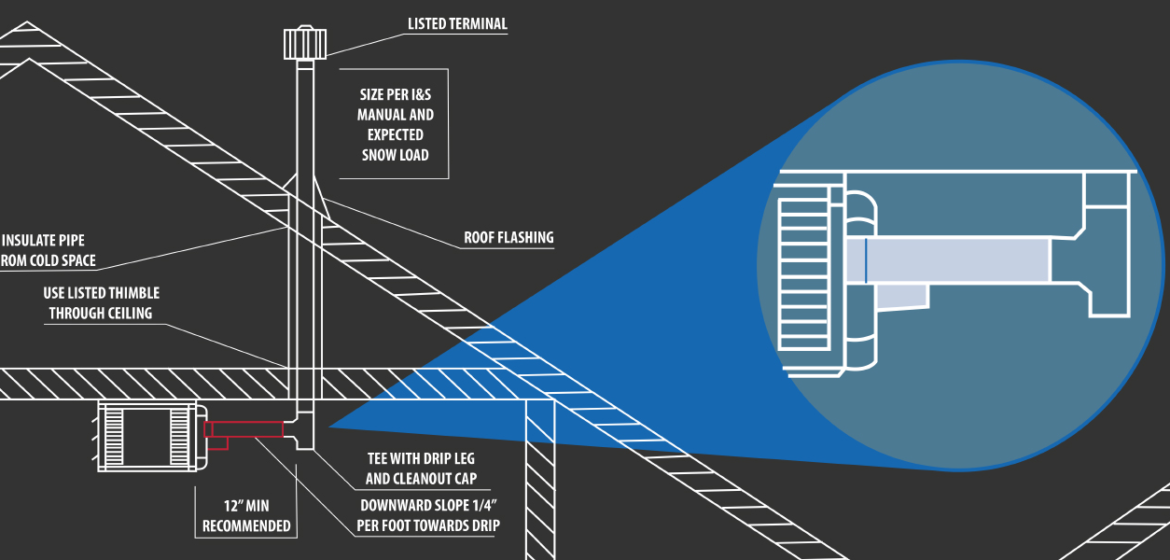

This code change, adopted in 2011, means all residential power-vented unit heaters requiring horizontal vent configurations must now conform to Category III venting requirements. The venting system must be gas-tight and meet certain construction criteria, as defined in UL1738, the standard for Venting Systems for Gas Burning Appliances, Categories II, III, and IV. Venting systems that are approved to meet the UL1738 standard can be found at Underwriters Laboratories and will be clearly marked with UL approval. These systems, which include seals and fasteners, are generally easier to install. This venting code applies to all manufacturers of gas-fired unit heaters.

Commercial or industrial power-vented units may be installed with either a listed vent system as described above, or with properly sealed single-wall metal vent pipe, which is outlined in the installation and service manual. For condensing appliances, the vents must be gastight and watertight. They must include ways to drain the condensate from the vent system. The vent temperature for these units is significantly lower than a power-vented or separated combustion unit, so PVC is adequate for these systems if it is primed and glued to create gastight and watertight joints.