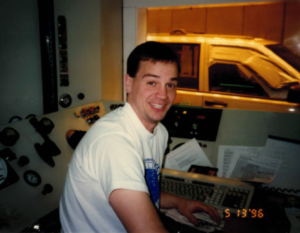

The Tunnel Rat from the Wobbly Hog

Marty Weishoff reflects on his climb up the Modine ladder

Marty Weishoff was working in a Kenosha Piggly Wiggly in 1991 when a friend suggested he apply for a job with Modine. Marty was pursuing a degree in fluid power at Gateway Technical College, and he rightly assumed Modine was a better fit for his skills than the “Wobbly Hog.”

Twenty-seven years later, he is the father of two teenagers and the engineering manager of the Racine Technical Center. He oversees the testing equipment, and responsible for 10 reports (nine in North America and one in Brazil). In addition, 18 technicians work in the Racine

Technical Center to complete tests.

His story is the latest in a series of interviews with Modine professionals.

Question: What was your original role at Modine?

Answer: I started out as a lab technician setting up and running tests. It was called the auto lab at that point, and it had a much smaller footprint than where we’re at today. We were known as the “tunnel rats,” because in the back room where we used to work was very hot and humid because we had steam heating the fluids. We had oil dripping, we had pipes rusting, we had a little bit of everything back there.

What’s the best thing about working for Modine?

The people. When I was a technician, there was a lot of interaction with the test requesters, which were the application engineering group or warranty group. As troubles would come up, the Tech Center and test requestor teamwork we’d be able to assemble to see things through was incredible. That’s still true today.

What has kept you there so long?

The opportunities. I had no idea what I was necessarily going to do with a mechanical engineering degree. The title of test engineer wasn’t even in my brain. Back in the day a lab manager was my first boss. I didn’t know there was a direct connection between a mechanical engineering and a test engineering role. I was finishing up at the Milwaukee School of Engineering right when the new tech center was opening up and that was the title they were looking for. One of the requirements was a mechanical engineering degree. I also had good experience in what to do and what not to do during those setups and interactions between the technicians and the test equipment because I lived it for several years.

So you got your mechanical engineering degree while working for Modine?

Yes, and they helped me pay for that education I was living at home in Kenosha. I’d come to work from 7 a.m. to 3:30 p.m. at Modine, and then I’d head up the Milwaukee School of Engineering for night classes. I’d finish up there and head back down to Kenosha and sleep there and do it all over again the next day. There were lots of miles going back and forth and a lot of hours of study.

What are the most interesting changes you’ve seen over the course of your Modine career?

The biggest change was back in 2000 when we made the transition from the auto lab to the tech center. But every day we continue to learn something new. The human brain is a pretty powerful thing and when you get locked into that “we’ve always done it this way” attitude you’ve got to dig a little deeper and consider, “Is that the best way?”

What does the future hold for Modine?

We can take it to whatever level we need to. I have an employee in Brazil who is the tech center manager there. I’m heavily involved with Germany. We have a tech center there. Business has been good for us over in China, so we’re talking about expanding more test equipment into other areas there. India also has some test facilities. We are getting to the point where we are truly worldwide, that’s for sure.

As technology evolves and consumer demand changes, do you expect any changes in products or the technology to develop and perfect these products?

Absolutely, especially with electric vehicles and heat exchangers. It’s a different style of heat exchanger. It’s still a heat exchanger, but what we are heating or cooling down is going to continue to change. That means the test engineering job is always going to be important. We need to make sure we can test that product.

What do you like to do outside of work?

I have two teenagers and am heavily involved with them and their sports. My son plays lacrosse and my daughter runs track. We did a lot of tent camping when they were very young, we’d bring the pack and play inside the tent. Then we had a small hybrid camper. Now we have a 28-foot camper. We’ve made it to Yellowstone with the camper, and in Wisconsin, the Dells area and the midstate. Our favorite place now is Holiday Shores, because you can rent boats. The kids have gotten into wakeboarding.

Are they exhibiting any of the mechanical aptitude of their father?

Oh boy. When they bring home that math homework and they don’t want to do it, they’d rather have an answer of “Well, no one can do it.” I may need to do a little research to remember how to solve some of the problems but it is satisfying when you get the correct answer. I really like helping them out with their math homework, but I think sometimes they wish I didn’t know how to do it, because then they’d say, “well, we can just do it tomorrow.”